Editing and Deleting Inventory Items

Learn how to update inventory items and manage stock adjustments.

✏️ Editing Inventory Items

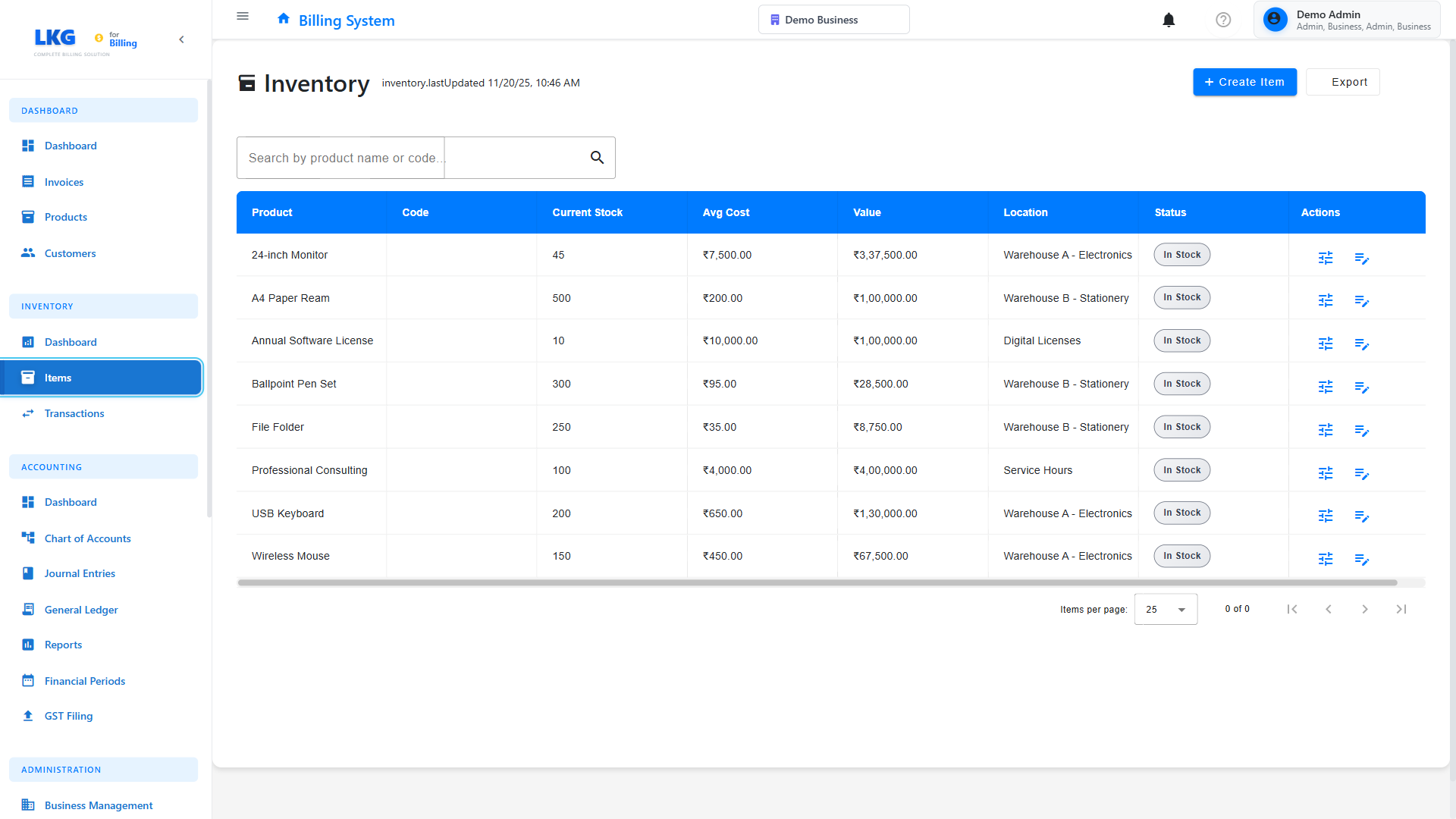

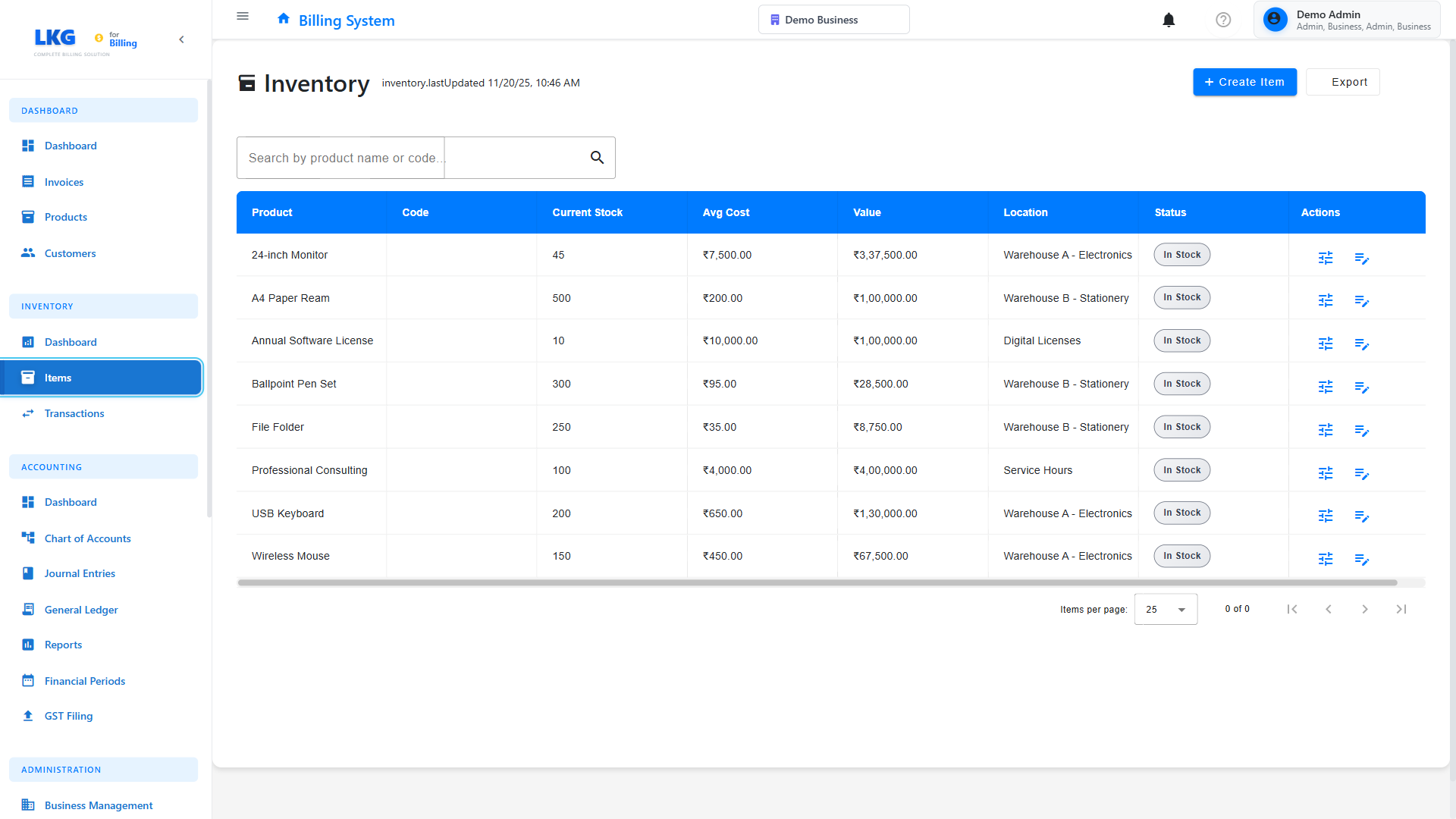

Accessing Inventory Edit

- Go to Inventory page

- Find the inventory item in the list

- Click Edit button (pencil icon)

- Or click Actions (⋮) → Edit

- Inventory item form opens with current data

Editable Fields

You can edit inventory item information:

Product Details:

- Product selection (can change to different product)

- Product name (read-only, from product master)

- Unit of Measurement (from product)

Stock Information:

- Current Stock Quantity (view only - use adjustments to change)

- Location/Warehouse

- Bin/Rack Location

- Lot Number / Batch Number

Thresholds:

- Low Stock Alert Level

- Reorder Point

- Reorder Quantity

- Maximum Stock Level

Tracking:

- Serial Numbers (for serialized items)

- Expiry Date (for perishable items)

- Manufacturing Date

Status:

- Active/Inactive

- Notes

Edit Restrictions

- Current stock cannot be edited directly in inventory item

- Use Stock Adjustments to increase/decrease stock

- This maintains proper audit trail

What You Can Edit:

✅ Location and bin information

✅ Reorder levels and thresholds

✅ Serial numbers and tracking info

✅ Active/Inactive status

✅ Notes

What You CANNOT Edit:

❌ Current stock quantity (use adjustments instead)

❌ Product history in invoices

❌ Past stock movement records

Changing Stock Quantity

To change stock quantity:

- Do NOT edit inventory item directly

- Go to Inventory → Adjustments

- Create a new adjustment:

- Increase Stock - For purchases, returns, corrections

- Decrease Stock - For damage, theft, corrections

- Enter reason and quantity

- Save adjustment

- Stock updated automatically

See Stock Adjustments for complete guide.

🗑️ Deleting Inventory Items

When You Can Delete

✅ Can Delete:

- Inventory items never used in invoices

- Inventory items with zero stock and no history

- Test inventory items

- Duplicate entries

❌ Cannot Delete:

- Items with current stock > 0

- Items used in finalized/paid invoices

- Items with adjustment history

- Items with transaction history

Delete Process

For eligible inventory items:

- Go to Inventory page

- Find the item to delete

- Ensure stock is zero

- Click Actions (⋮) → Delete

- Confirm deletion

- Item permanently removed

What Gets Deleted

When you delete an inventory item:

Deleted:

- Inventory tracking record

- Location information

- Reorder settings

- Notes and tags

NOT Deleted:

- Product master data (remains in Products)

- Invoice references (preserved on invoices)

- Stock adjustment history (if any - blocks deletion)

- Transaction records (blocks deletion)

Cascade Effects

Deleting Inventory Item:

- Does NOT delete the product

- Only removes inventory tracking

- Product still exists in Products list

- Can re-enable inventory tracking later

If Item Has Stock:

- Cannot delete until stock is zero

- Must adjust stock to zero first

- Or perform a stock write-off

If Item Has History:

- Cannot delete if adjustments exist

- Cannot delete if used in invoices

- Mark as Inactive instead

Alternative to Deletion

Marking as Inactive

Better alternative to deletion:

- Edit the inventory item

- Toggle Active Status to Inactive

- Item hidden from:

- Active inventory lists

- Stock adjustment screens

- Low stock alerts

- Still visible in:

- Historical reports

- Past invoices

- Can reactivate anytime

Benefits:

- Preserves all history

- Maintains audit trail

- Can restore if needed

- Compliant with accounting standards

Zero Out Stock

For discontinued items:

- Perform stock adjustment to bring stock to zero

- Document reason (discontinued, obsolete, etc.)

- Mark item as Inactive

- Keep for historical reference

Stock Adjustments vs. Item Deletion

Stock Adjustments

Use adjustments to:

- Increase stock (purchases, corrections)

- Decrease stock (damage, theft, loss)

- Correct counting errors

- Write off obsolete stock

Process:

- Go to Inventory → Adjustments

- Select New Adjustment

- Choose product

- Enter quantity change

- Enter reason

- Save adjustment

See Stock Adjustments for details.

Item Deletion

Use deletion to:

- Remove inventory tracking for a product

- Clean up test data

- Remove duplicate entries

- Stop tracking a product

Not Used For:

- Reducing stock to zero (use adjustment instead)

- Removing from invoices (cannot do this)

- Correcting stock errors (use adjustment instead)

Common Scenarios

Scenario 1: Stop Tracking a Product

Problem: Product no longer needs inventory tracking.

Solution:

- Adjust stock to zero (if any stock exists)

- Document reason in adjustment

- Delete the inventory item

- Product still exists in Products, just not tracked for inventory

Scenario 2: Duplicate Inventory Item

Problem: Same product tracked twice in inventory.

Solution:

- Identify which record is correct

- Check which has transaction history

- If duplicate has NO history: Delete it

- If both have history:

- Consolidate stock using adjustments

- Mark duplicate as inactive

- Add note: "Duplicate of [Product Name]"

Scenario 3: Wrong Product Linked

Problem: Inventory item linked to wrong product.

Solution:

- If no history: Delete inventory item, recreate with correct product

- If has history:

- Cannot easily change product linkage

- Mark as inactive

- Create new inventory item with correct product

- Add notes to both explaining the issue

Scenario 4: Obsolete Inventory

Problem: Product obsolete, need to write off stock.

Solution:

- Create stock adjustment: "Write-off - Obsolete"

- Reduce stock to zero

- Mark inventory item as Inactive

- Keep for audit/historical records

- Do NOT delete (preserves history)

Scenario 5: Test Inventory Data

Problem: Test inventory items created during setup.

Solution:

- Ensure items have zero stock

- Ensure no adjustment history

- Delete the inventory items

- Products can remain in Products list or be deleted separately

Editing Stock Locations

Changing Warehouse

To move inventory to different location:

Option 1: Edit Location

- Edit inventory item

- Change Location/Warehouse field

- Save changes

- Stock now tracked in new location

Option 2: Transfer (if feature available)

- Create stock transfer

- From: Current location

- To: New location

- Quantity: Amount to transfer

- Complete transfer

- Stock updated in both locations

Multi-Location Tracking

If system supports multiple locations:

- Each location has separate inventory item

- Product can have inventory in multiple warehouses

- Total stock = sum of all locations

- Edit each location separately

Reorder Levels

Editing Thresholds

Keep inventory properly stocked:

Low Stock Alert Level:

- System alerts when stock falls below this level

- Edit based on consumption rate

- Receive email/notification when low

Reorder Point:

- When to place new order

- Usually slightly higher than low stock level

- Account for lead time

Reorder Quantity:

- How much to order when reordering

- Based on supplier minimums, usage rate

- Economic order quantity

Maximum Stock:

- Upper limit to avoid overstocking

- Based on storage capacity, shelf life

Updating Settings

- Edit inventory item

- Adjust threshold values

- Save changes

- System uses new thresholds immediately

Serial Number Tracking

For Serialized Items

Items like electronics, equipment:

Adding Serial Numbers:

- Edit inventory item

- Go to Serial Numbers section

- Add serial numbers (comma-separated or one per line)

- System tracks each serial individually

- When sold, specific serial marked as sold

Editing Serial Numbers:

- Can add new serials

- Cannot delete serials used in invoices

- Can mark serials as damaged/returned

Deleting Item with Serials:

- Cannot delete if serials exist

- Must clear all serials first (if no sales)

- Or mark item as inactive (if serials sold)

Batch/Lot Number Tracking

For Batched Items

Items like food, chemicals:

Editing Batch Info:

- Edit inventory item

- Update Lot/Batch Number

- Update Manufacturing Date

- Update Expiry Date

- Save changes

Multiple Batches:

- If system supports, track multiple batches per product

- Each batch has own expiry, quantity

- Edit each batch separately

- FIFO/FEFO rules may apply

Deleting Item with Batches:

- Cannot delete if batches have history

- Must deplete or write off all batches

- Mark as inactive instead

Data Integrity

Related Records Impact

Before deleting inventory item:

Stock Adjustments:

- Any adjustments prevent deletion

- Must have zero history to delete

Invoices:

- Product on finalized invoices prevents deletion

- Inventory tracking preserved on invoices

Reports:

- Inventory reports reference the item

- Deletion creates gaps in historical data

Alerts:

- Low stock alerts based on item

- Deletion removes from monitoring

Audit Trail

Inventory changes are logged:

Edit Log Includes:

- Who edited (user name)

- When edited (date and time)

- What changed (field names and values)

- Old and new values

Example:

Inventory Item Updated

Date: Nov 20, 2024 4:00 PM

User: Admin User

Product: Wireless Mouse (SKU: WM-001)

Changes:

- Reorder Point: 20 → 30

- Low Stock Alert: 10 → 15

- Location: Warehouse A → Warehouse B

Deletion Log:

Inventory Item Deleted

Date: Nov 20, 2024 4:15 PM

User: Admin User

Product: Test Product (SKU: TEST-001)

Stock at Deletion: 0

Reason: Test data cleanup

Bulk Operations

Bulk Edit Inventory

Update multiple items:

- Go to Inventory page

- Select items using checkboxes

- Click Bulk Actions → Edit Selected

- Change common fields:

- Location

- Reorder settings

- Active/Inactive status

- Click Apply to All

Bulk Adjustments

Adjust stock for multiple items:

- Go to Inventory → Adjustments

- Select Bulk Adjustment

- Choose multiple products

- Enter quantities for each

- Enter common reason

- Save bulk adjustment

- All stocks updated at once

Bulk Activate/Deactivate

Quick status changes:

- Select inventory items

- Click Bulk Actions → Activate or Deactivate

- All selected items updated

Best Practices

Before Editing

- Verify item - Ensure editing correct product

- Check stock - Review current stock levels

- Document changes - Note why you're editing

- Use adjustments - Never edit stock quantity directly

Before Deleting

- Verify zero stock - Ensure no stock exists

- Check history - Ensure no adjustments or invoices

- Export data - Save info if needed for records

- Use inactive - Safer than deletion

Inventory Maintenance

Regular tasks:

- Daily: Monitor low stock alerts

- Weekly: Review reorder points

- Monthly: Perform stock takes, verify counts

- Quarterly: Clean up inactive items

- Annually: Review and archive obsolete items

Permissions

Who Can Edit/Delete

Admin Users:

- Edit all inventory items

- Delete items (if eligible)

- Bulk operations

- Stock adjustments

Inventory Managers:

- Edit inventory items

- Stock adjustments

- Cannot delete items with history

Regular Users:

- View inventory

- Limited edit access

- Cannot perform adjustments

Read-Only Users:

- View only

- No edit or delete permissions

Troubleshooting

Cannot Edit Inventory Item

Problem: Edit button grayed out.

Solutions:

- Check permissions

- Verify item not locked by another user

- Refresh the page

- Contact administrator

Cannot Delete Inventory Item

Problem: Delete option fails or unavailable.

Reasons:

- Item has stock > 0

- Item has adjustment history

- Item used in invoices

- Insufficient permissions

Solution:

- Adjust stock to zero first

- Or mark as Inactive instead of deleting

Stock Not Updating

Problem: Edited item but stock didn't change.

Explanation:

- Stock quantity cannot be edited directly

- Must use Stock Adjustments to change quantity

- This is by design for audit purposes

Solution: Use Inventory → Adjustments to change stock.

Changes Not Saving

Problem: Edits not persisting.

Solutions:

- Check for validation errors

- Ensure required fields filled

- Verify numbers are valid

- Check permissions

- Refresh and try again

Next Steps

- Inventory Overview - Understanding inventory management

- Stock Adjustments - Adjusting stock quantities

- Reports - Inventory reports and analysis

Important: Never edit stock quantities directly. Always use Stock Adjustments to increase or decrease inventory. This maintains a proper audit trail and ensures compliance with accounting standards.