Managing Inventory Items

Learn how to create, edit, and manage inventory items to track your stock levels effectively.

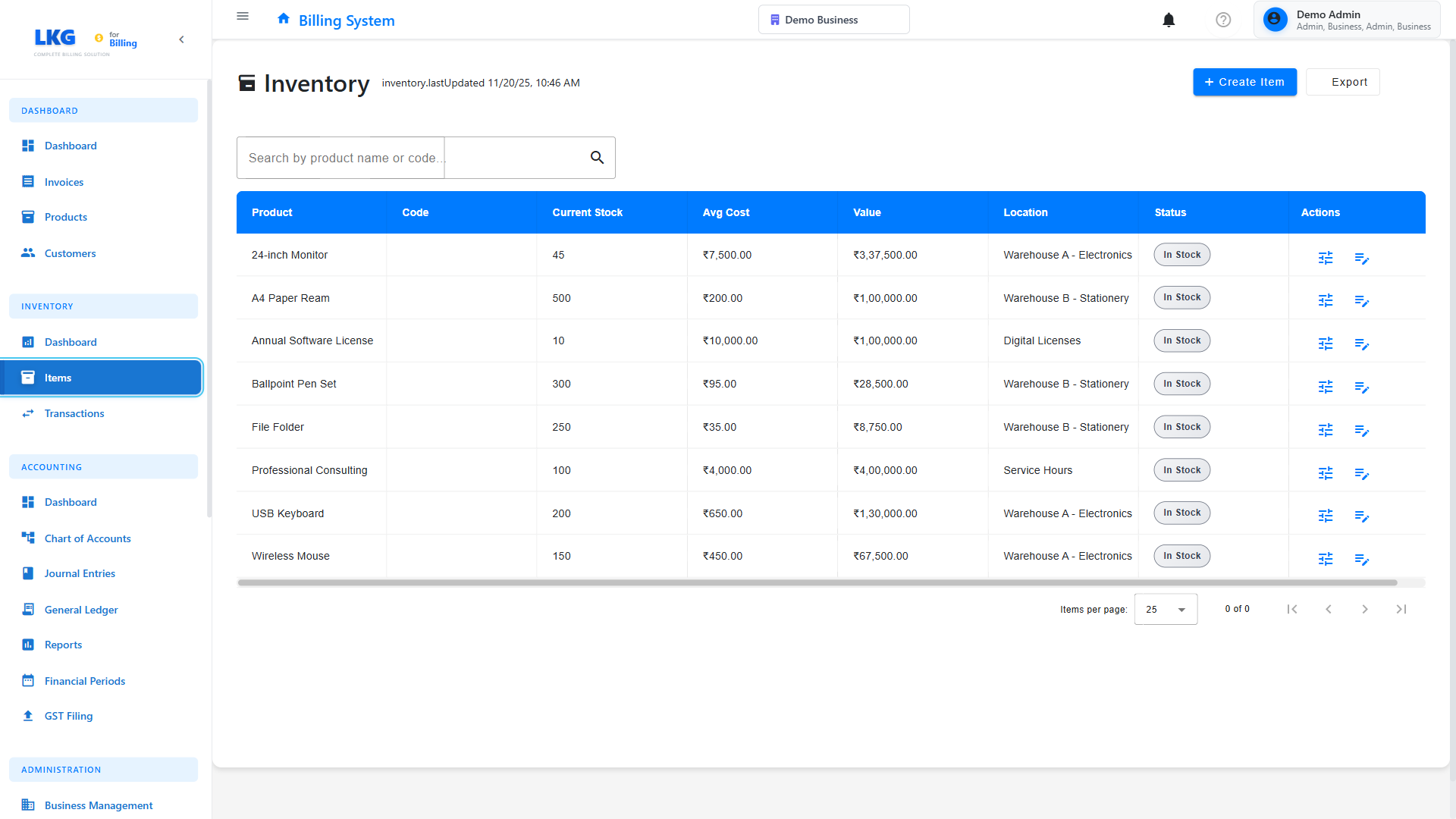

Inventory Items List

The Inventory Items page displays all products you're tracking with their current stock status.

Viewing Inventory

The inventory list shows:

- Product Name - Name and SKU of the item

- Current Stock - Available quantity

- Minimum Stock - Reorder threshold

- Unit Cost - Cost per unit

- Total Value - Current stock × unit cost

- Status - Stock level indicator

- 🟢 In Stock - Above minimum level

- 🟡 Low Stock - At or near minimum level

- 🔴 Out of Stock - Zero quantity

Quick Actions

From the inventory list, you can:

- View Details - See complete item information

- Adjust Stock - Add or remove stock

- Edit Item - Update product details

- View History - See all transactions

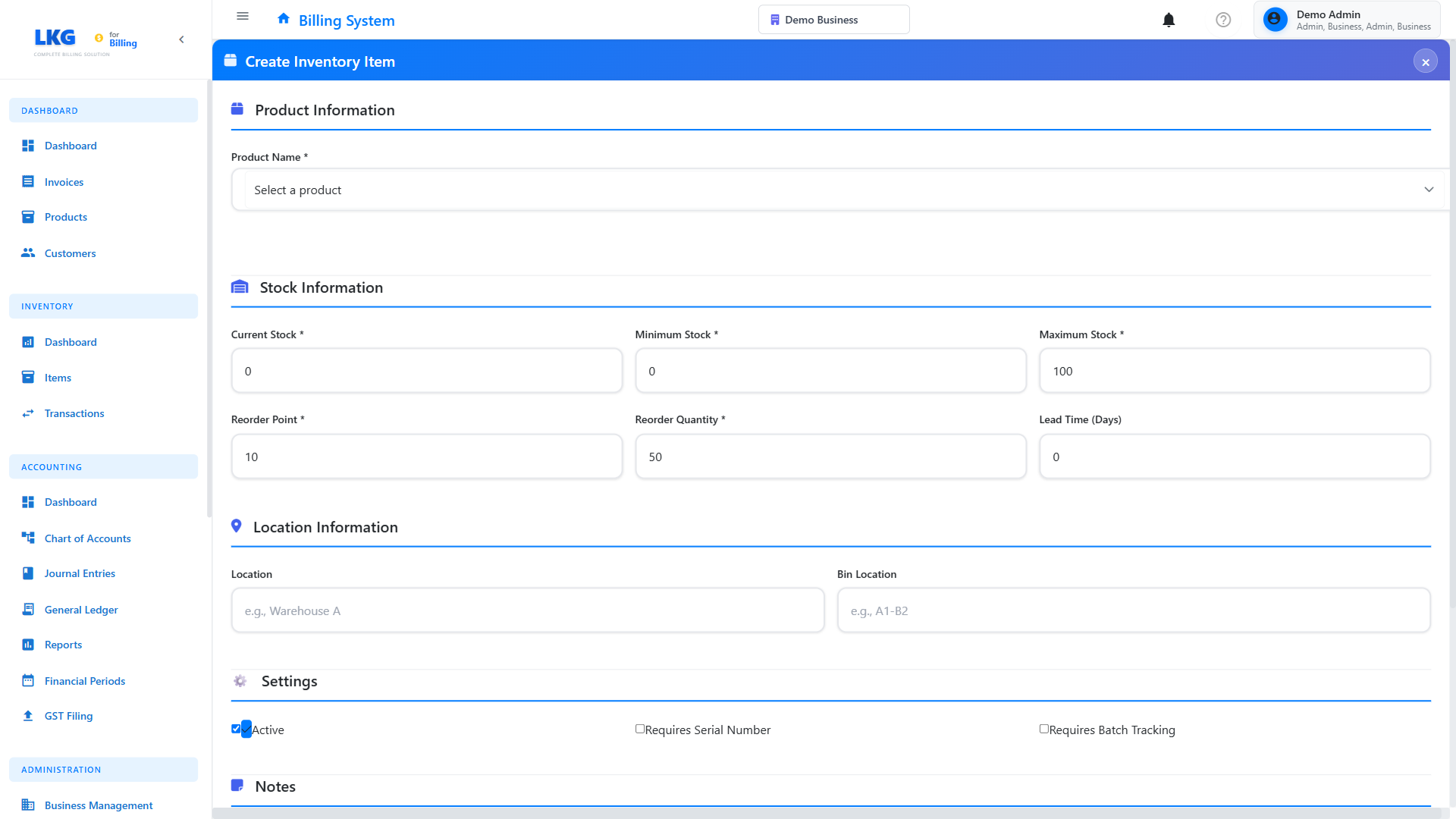

Creating an Inventory Item

Step 1: Start New Item

- Navigate to Inventory → Items

- Click "Create Item" button

- The inventory item form opens

Step 2: Enter Basic Information

Product Selection (Required)

Select the product from your product catalog. Only products that don't already have inventory items can be selected.

SKU/Product Code

- Automatically filled from product

- Can be edited if needed

- Must be unique across inventory

Current Stock Quantity (Required)

The initial quantity you have in stock:

Examples:

- 100 (100 units)

- 50.5 (50.5 kg for weight-based items)

- 0 (if setting up before receiving stock)

Minimum Stock Level (Required)

The threshold that triggers low stock alerts:

Examples:

- 10 (reorder when 10 or fewer remain)

- 25 (for high-demand items)

- 5 (for slow-moving items)

Maximum Stock Level

Optional upper limit for reordering:

Example:

- Minimum: 10

- Maximum: 100

- Reorder when: ≤ 10

- Order quantity: to reach 100

Step 3: Cost Information

Unit Cost (Required)

The cost per unit of the product:

Examples:

- ₹500 (cost price per unit)

- ₹1,250 (average cost for varying prices)

Unit cost is used to calculate inventory value. Update it when you purchase at different prices to maintain accurate valuation.

Unit of Measure

Specify how the product is measured:

- Piece/Unit - Individual items

- Box/Carton - Packaged quantities

- Kg/Gram - Weight-based

- Liter/ML - Volume-based

- Meter - Length-based

Step 4: Storage & Location

Storage Location

Physical location where item is stored:

Examples:

- "Warehouse A - Shelf 12"

- "Main Store - Section B3"

- "Cold Storage - Bay 5"

Bin/Rack Number

Specific storage identifier:

Examples:

- "A-12-03"

- "R15-S02"

- "CS-05-L"

Step 5: Save the Item

- Review all entered information

- Click "Save" button

- The new inventory item appears in the list

- Initial stock quantity is recorded as a transaction

Editing Inventory Items

Update Item Details

-

Find the item in the inventory list

-

Click the Edit icon

-

Modify the fields:

- Unit cost (affects future calculations)

- Minimum/maximum stock levels

- Storage location

- Product details

-

Click "Save" to apply changes

Don't change current stock quantity through edit. Use Stock Adjustments to change quantities - this maintains proper transaction history.

Stock Level Indicators

Status Colors

🟢 In Stock (Green)

Current Stock > Minimum Stock

Example: Current: 50, Minimum: 10

Status: Healthy stock level

🟡 Low Stock (Yellow)

Minimum Stock < Current Stock ≤ (Minimum Stock × 1.5)

Example: Current: 12, Minimum: 10

Status: Order soon

🔴 Out of Stock (Red)

Current Stock = 0

Status: Urgent - Cannot fulfill orders

Inventory Valuation

Total inventory value is calculated as:

Total Value = Current Stock × Unit Cost

Example:

- Product A: 50 units × ₹500 = ₹25,000

- Product B: 30 units × ₹1,200 = ₹36,000

- Product C: 75 units × ₹300 = ₹22,500

----------------------------------------

Total Inventory Value = ₹83,500

Bulk Operations

Export Inventory Data

Export your inventory for:

- Backup purposes

- External analysis

- Reporting to stakeholders

- Audit requirements

- Click "Export" button

- Choose format (CSV, Excel)

- Download the file

Import Inventory (Future Feature)

Bulk import capabilities coming soon for:

- Initial setup with large catalogs

- Regular stock updates

- Migration from other systems

Best Practices

Setting Minimum Stock Levels

Calculate based on:

-

Average Daily Sales

If you sell 5 units/day on average:

Minimum Stock = 5 × Lead Time Days + Safety Buffer

Example: 5 × 7 days + 5 buffer = 40 units -

Lead Time

- Time to reorder and receive stock

- Add buffer for delays

-

Sales Variability

- Higher variability = higher minimum

- Seasonal peaks require adjustment

Maintaining Accurate Costs

Update unit costs when:

- ✅ Purchasing at new price

- ✅ Receiving supplier price updates

- ✅ Costs include shipping/duties

- ✅ Volume discounts affect average cost

Cost calculation methods:

- FIFO (First In, First Out) - Use oldest cost

- Average Cost - Calculate weighted average

- Last Purchase - Use most recent cost

Storage Organization

Organize by:

- Product category

- Sales frequency (fast-movers near front)

- Size/weight

- Special requirements (temperature, security)

Troubleshooting

Cannot Create Inventory Item

Problem: Product not available in dropdown

Solutions:

- Check if product already has an inventory item

- Create the product first in Products module

- Ensure product is active

Incorrect Stock Value

Problem: Total value seems wrong

Solutions:

- Verify unit cost is correct

- Check current stock quantity

- Review recent transactions

- Make stock adjustment if needed

Missing Items in List

Problem: Cannot find an inventory item

Solutions:

- Use search feature

- Check if item was deleted

- Verify filters are not applied

- Refresh the page

Next Steps

- Stock Adjustments - Learn how to adjust stock levels

- Transaction History - View all stock movements

- Inventory Dashboard - Monitor overall inventory health

Pro Tip: Review and update your minimum stock levels quarterly based on actual sales patterns to optimize inventory management.